Case study on surface control optics

Light roof over the press discharge area

BSH Bosch und Siemens Haushaltsgeräte GmbH, Traunreut / Nauen

Initial Situation

BSH Bosch und Siemens Hausgeräte GmbH is one of the market leading companies in the white goods industry. In the manufacture of pressed parts an increased number of surface errors occurred which eventually reached the assembly section. An analysis of BSH quality management showed that surface controls were quite complicated under the existing lighting conditions. Surface controls thus developed a concept to optimize the lighting of the entire press discharge area without influencing the respective work cycles.

Approach / Challenge

In close cooperation with the quality management of BSH surface controls analyzed the local circumstances. In this context the problematic lighting conditions in the press discharge area were recognized and addressed. Special optics, controlled by a semiautomatic brightness control, have been installed to prevent the formation of shades, ambient light effects and reflections.

A great challenge was the positioning of the optics in the production plant, because they are partly restricted by the routes of the lift trucks as well as by the close arrangement of the containers in the press shop. The different textures of the pressed parts created another challenge. Using different test settings and different optics the various sample parts were analyzed and evaluated in the lighting laboratory of surface controls.

Solution

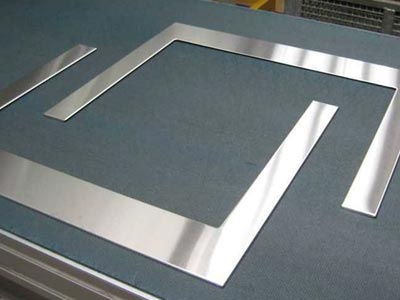

A surface inspection system, which is optimally harmonized with the work cycles, was developed for the press discharge area. A light roof construction with LensPrismDarkfieldOptic (LPS 50) over the press discharge area helps employees of BSH to a better visual evaluation of the pressed parts. As a consequence the error rate as well as the costs could be markedly reduced.

The lighting concept has successfully proven itself in the production area and has already been employed many other times in the company. Furthermore, the production management and the internal quality management of BSH recommended the implementation of the surface control system at other production sites of BSH and its subcompany.