Perfect light – perfect surface control

Basics

In the scope of quality control, light and therefore lighting is very important. For the human inspectors to precisely control surfaces with their measuring instruments, the eyes, lighting conditions must be created facilitate recognition of surface defects.

The seeing functions relevant for surface inspection are visual acuity and contrast perception.

Contrast perception (contrast vision) is the ability to perceive brightness differences between two adjacent surfaces (contrasts).

The perception of contrasts depends, among others, on the adaption luminance and therefore the adaption level of the eye. The greater the ambient luminance, the brighter the room, the greater the relevant contrast sensitivity. At low contrasts and small seen objects, the seen object may be turned from invisible to visibly by an increase of ambient luminance (brightness).

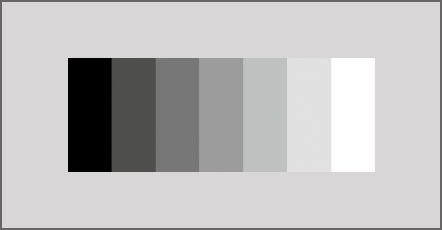

Example for contrast

However, ambient luminance cannot be increased without limit. If it is too high, it will lead to a blinding glare. To avoid this problem, lenses are used to increase the contrast of the surface defect. This measure facilitates error recognition at a low luminance already and thus redices the glare.

Visual acuity (medically: visus) corresponds to the resolution capacity of the eye. The resolution capacity is the ability of the retina to perceive two points as separate.

Visual acuity depends on the adaption luminance and the contrast. Increasing adaption luminance will also lead to increasing visual acuity. For surface inspection, this means that high ambient brightness positively influence the employees’ visual acuity.

Seeing and recognition is highly relevant for surface inspection. The eye not only distinguishes brightness contrasts, but also, for example, color contrasts.