adomea scanner

Fully automated surface inspection supported by artificial intelligence

The adomea scanner is redefining the possible in terms of automotive quality control and is setting new standards in the field of surface inspection. The adomea scanner based on artificial intelligence (AI) is being implemented within production processes for the fully automated inspection of car body surfaces.

Essentially, the adomea scanner is an LED tunnel consisting of a large number of individually controllable LEDs. These LEDs generate light patterns in different colors, which are reflected by the surface of the vehicle. The tunnel is equipped with 20 high-resolution cameras. During the scanning process – which takes just 45 seconds – the adomea scanner captures precise measurement signals which it uses to analyze the car body surface. Supported by artificial intelligence (AI), the scanner is then able to automatically detect, classify, and assess any damage.

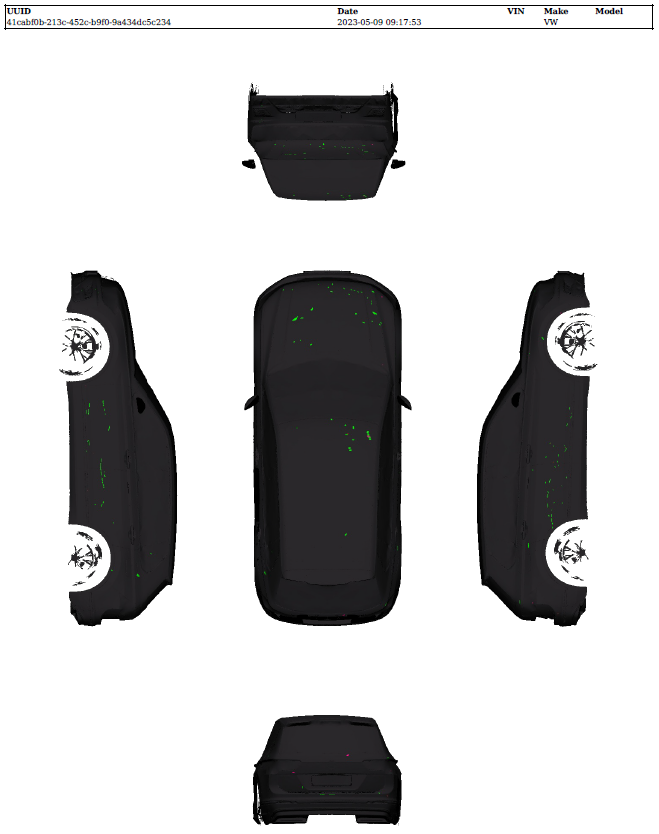

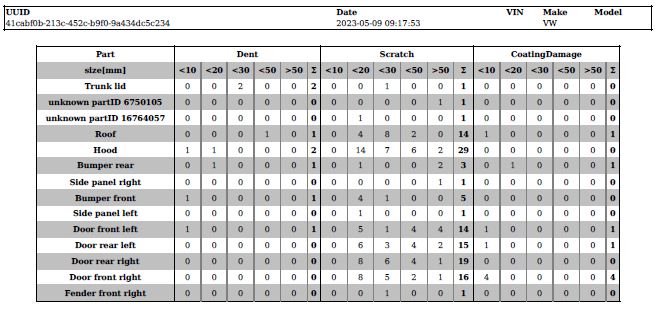

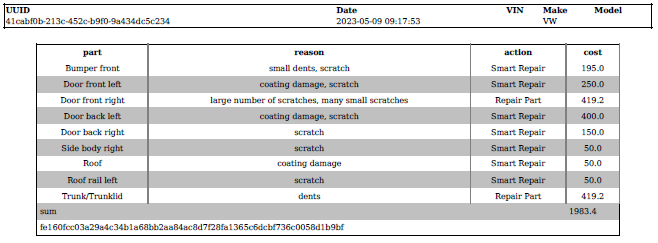

The automated assessment of the information obtained by the scan can be generated in various ways. Surface defects can be displayed as a 3D model or clearly summarized in the form of a final report.

Overall, the adomea scanner provides innovative quality control with a high degree of automation. It allows measurements to be taken quickly and can also be trained to identify specific types of damage. Further, those using the scanner can define their own threshold values. These are the values above which damage will be recorded and assessed. This allows potential defects to be detected early on and helps eliminate production faults.

Cooperation

Our top priority is to consistently offer our customers new solutions designed to make the automotive surface inspection process easier. In 2023, TÜV Rheinland and OLIGO Lichttechnik GmbH – surface controls began working together on the adomea scanner. The technological development of the required artificial intelligence (AI) is the responsibility of TÜV Rheinland (long-term development project), whilst the scanner is manufactured and distributed by OLIGO surface controls with an emphasis on quality – something the company is known for.

Defect detection

Forms of error detection

- Dents

- Scratches

- Rock falls

- Chipped paint

- Customized labeling

Formen der Fehlererkennung

- Dents

- Scratches

- Rock falls

- Chipped paint

- Deformations

- Adhesive/Foil residues

- Body damage

- Missing parts

- Deformations

- Adhesive/Foil residues

- Body damage

- Missing parts

The adomea scanner boasts the following features

- 200K individually controllable LEDs

- System operation via a tablet

- 20 high-resolution cameras

- Measurement resolution of up to 300 micrometers

- Measuring time of just 45 seconds

- Assessment time of just 60 seconds

- Automatically opening doors ~ 1 second

Ultimate precision thanks to a combination of multidimensional measuring signals

In contrast to conventional systems, the adomea scanner not only uses high-resolution images, but combines these with the information from color images, surface reflectivity, and surface curvature to produce a uniquely detailed assessment using artificial intelligence (AI).

Main measuring signals

- Color image

- Surface curvature

- Surface reflectivity

Color image

Certain types of damage can be detected using color images, this includes damage caused by larger stone chips.

Surface curvature

Scratches to the surface of a vehicle will often get missed by color images. Using surface reflectivity, however, ensures these scratches are detected.

Surface reflectivity

Scratches to the surface of a vehicle will often get missed by color images. Using surface reflectivity, however, ensures these scratches are detected.

Documenting results

The adomea scanner detects bodywork damage and irregularities quickly and accurately. It then provides the results of this analysis and information on the damage detected and classified by AI in various different formats. The scanner reliably creates summary reports with graphs and diagrams, images, and lists.

Sample report